Analysing Machine Insulation with Partial Discharge Testing

December 9, 2022

LIVE HV provides online Partial Discharge (PD) monitoring for rotating machines to accurately determine the asset’s insulation condition. Measurements can be taken from pre-installed PD sensors throughout the asset’s lifespan, without the need for an outage. This can be performed continuously, for optimum condition comprehension, or periodically.

Heatmap phase resolved PD pattern analysis software can diagnose and differentiate between end-winding and slot-section type PD, enabling focussed and efficient maintenance. Using this expert data analysis software and algorithms, the frequency of detected PD pulses is used to segregate different failure modes and identify any defects and their levels of criticality.

The following article describes how we recently analysed a machine’s insulation.

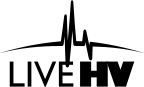

When selecting an area of low frequency PD pulses, we can detect slot-section PD that has originated from much deeper into the machine windings. Examining the shape and predominance of the phase pattern, we can ascertain what type of phase-to-earth PD is occurring and diagnose the criticality. These defects could arise from voids or delamination’s in the main insulation, the turn insulation or the corona protection layer (CPL). The example shown below examines pulses of less than 10 MHz as highlighted green.

Figure 1 Low Frequency PD pulses

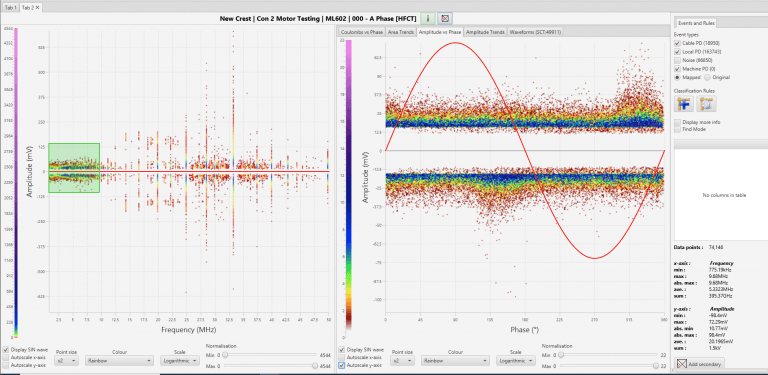

By selecting an area of high frequency PD pulses, we can detect end-winding PD that emanates much closer to the coupling capacitor sensors installed inside the machine termination box. The phase-to-phase PD is occurring between the 3 phases at the end-winding region. This type of PD is much easier to repair as the rotor doesn’t need to be removed for an inspection. Principally any damage to the insulation is caused by inadequate stress control, insufficient clearances and/or contamination. This can be seen in the image with the pulses of more than 25 MHz selected highlighted.

Figure 2 High Frequency PD pulses

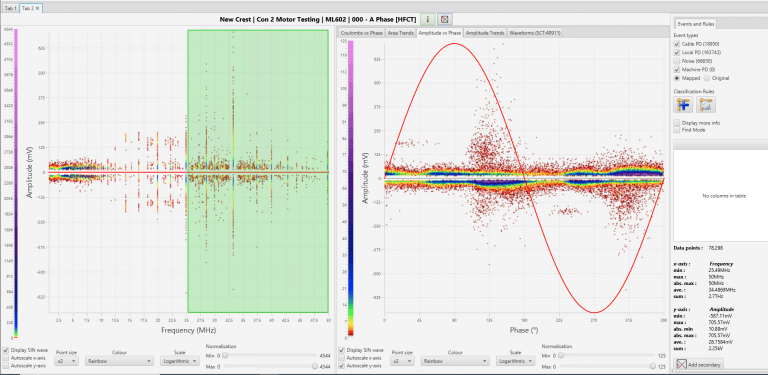

Software and techniques additionally identify unwanted noise clusters which can be disregarded. This assists further in future testing where bespoke filtering can be applied for maximum PD detection without the interference of noise. The below plot displays noise for this example.

Figure 3 Noise Frequency

Pre-installed PD sensors permit nonintrusive condition monitoring of rotating machines. This maximises the assets lifespan, prevents unplanned outages and reduces the reliance of traditional offline scheduled maintenance. Talk to LIVE HV about how we can install or monitor your machine PD sensors.