Machines – Motors & Generators

Maximising high voltage network integrity, keeping you online, all the time.

Machines – Motors & Generators

LIVE HV provides a complete range of high voltage testing services for motors & generators. From in-service and offline condition assessment testing to correct installation of sensors for periodic or continuous online measurement

Our services

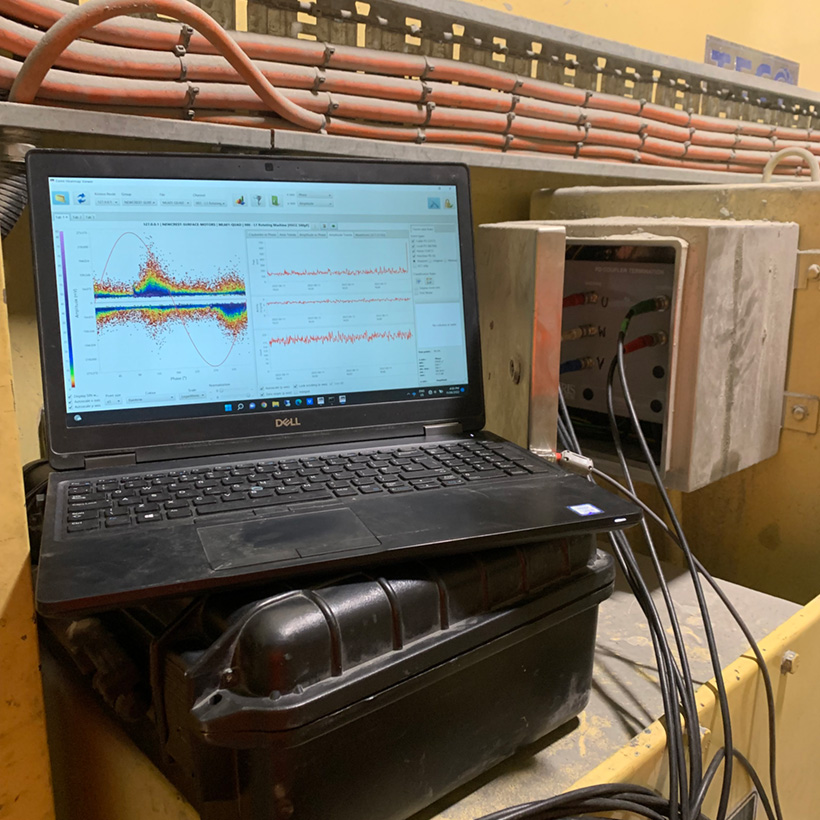

Online Diagnostic PD Testing

On-Line PD testing is widely accepted as the best condition assessment tool for motors and generators rated from 6.6 kV to 30 kV. Testing can be made using portable or permanent High Frequency Current Transformers (HFCT’s) or permanently installed coupling capacitors.

Key Benefits

- Identify & monitor insulation damage prior to failure

- Spot testing or continuous monitoring

- Differentiate between slot section & end winding discharge

- Monitor from remote end of HV cable if machine is in a hazardous area

- Monitoring with split core HFCT’s if no coupling capacitor is installed

Motor Current Signature Analysis (MCSA)

MCSA is a non-intrusive, on-line test technique, used to assess the rotor condition of motors by analysing the frequency content of the current.

MCSA can be used in conjunction with on-line partial discharge (OLPD) testing; for the preventative maintenance and diagnosis of problems in induction motors. Through periodic testing it is possible to track and trend a machine’s mechanical performance, pre‑empting faults and unplanned outages.

What Can MCSA Detect?

- Broken Rotor Bars

- Dynamic Eccentricity

- Static Eccentricity

Key Benefits

- Non-intrusive testing by analysing the frequency content of the 50/60 Hz current waveform through the motor

- Can provide savings by preventing in service failure of the motor

- Detects electrical problems with the rotor

- Complements On-Line PD testing

Offline Testing & Inspection

Offline testing of your machine incorporates diagnostics from partial discharge, tan delta and winding resistance among others. The ability to induce and control the voltage while testing allows for a thorough condition assessment.

When the machine is out of service this is an opportune time for sensor installation, internal inspections and general cleaning.

Offline Machine Testing Services

- Partial Discharge

- Dielectric Dissipation Factor (DDF) / Tan Delta (TD)

- PD Sensor Installation

- Rotor & Stator Insulation Resistance (IR) & Polarisation Index (PI)

- Winding Resistance

Continuous Monitoring

For Critical Plant it can be best practice to have permanent 24/7 monitoring which provides ultimate peace of mind regarding a machine’s condition. LIVE HV can provide, install & monitor a range of portable & permanent monitoring solutions, including hazardous area installations. We have the option of renting or purchasing monitoring equipment.

Key Benefits

- Installation & monitoring provided

- Service contracts for data analysis & monitoring equipment

- Rental options available

- Transportable options can be moved around site by the customer

- Remote access for real-time monitoring

Case Studies

Read more for examples of LIVE HV providing engineering and service solutions for our partners.

HV maintenance testing on a range of assets was undertaken during the scheduled sitewide shutdown at a gas plant.

Following a period of online condition monitoring, where performance degradation had been identified, the decision was made to replace the critical distribution transformer at a gas plant.

A pipeline across Queensland comprised of several pumping stations. The machines at six of these pumping stations were monitored, while