VLF or VLF PD Cables?

December 22, 2023

Traditionally commissioning testing of a cable involves Insulation Resistance and a VLF withstand test. This is starting to change though with Partial Discharge testing during cable commissioning becoming more popular.

A straight VLF withstand test is fairly simple to do, but you need to ask what it is achieving. The test involves placing an overvoltage on the cable, typically 2 to 3 times higher than the rated voltage, and seeing if the cable can survive. The test is pass/fail and there is little in the way of diagnostic information provided. In our experience, most cables will pass a VLF test even with significant issues that will lead to a limited service life before failure.

Except for some of the early vintage steam-cured XLPE cables, and where external damage has occurred, nearly every cable failure will be at a joint or termination. These joints and terminations will often discharge from the day of installation and will have PD (often for several years) before failure. The best way to detect this localised breakdown of the insulation is with a PD test. The voltage does not need to be taken as high as a withstand test and far more valuable information as to the cable condition can be gained.

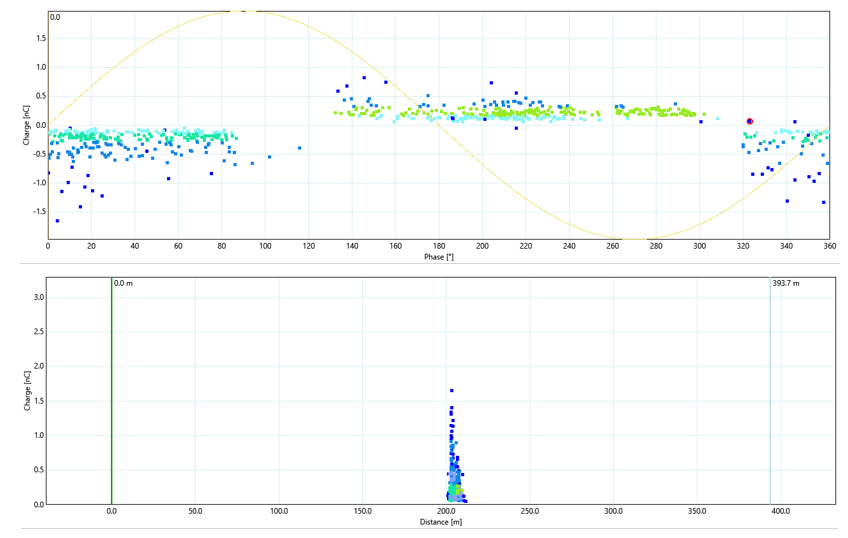

Take for example a cable we tested during commissioning this week on a solar farm. Often a simple VLF test would have been provided but we recommended a PD test be included. PD was detected on several of the cable joints. The PD magnitude was low however the PD was active below service voltage, meaning the cable will be deteriorating during regular service operating conditions and eventually fail. A decision was made to carry on with the VLF test (albeit at a lower voltage than originally planned) and a repair has been scheduled.

So the cable was commissioned but works have been planned which will significantly extend the cable life. Without the PD testing this information would never have been known until the joint failed and caused an unplanned outage.

The drawbacks of the PD test are that it is more complex to perform and the test set-up and equipment are pivotal. A ‘false negative’ can easily happen with poor noise-to-signal ratios. Similarly ‘false positives’ can easily occur due to incorrect set-up.

If the cable is critical and you have an experienced technician then including a PD test is an easy decision.